Machine ID card

Nationality

Made in FranceDosing program

DEBIPACK V 2.0Specifications

Filling/capping stations within the same cabin

Volume or weight range

From 100 ml to 30 liters depending on frame and projectCadence

700/800 cans per hour depending on number of filling headsFilling technology

FlowmeterPower supply

By pump or hopper depending on choice of dosing technologyAlimentation bouchons

Belt conveyor with manual feed or automatic dispenserFields of expertise

Secteur

Cosmetics

Chemistry

Food industry

Emballages

Rectangular

Ronds

Cylindrical

Applications particulière

ATEX

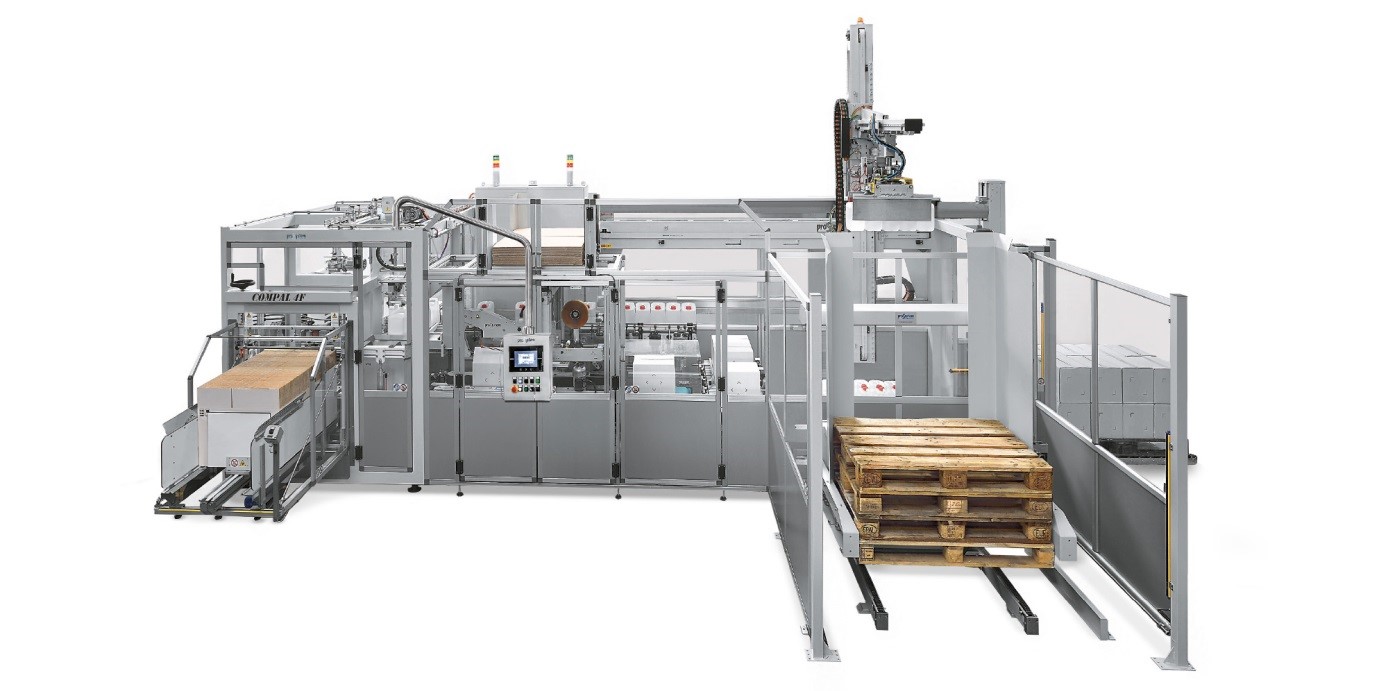

Complementary machines

PAC 321

PAC 400 range